It can be specially customized according to your measured size, environmental noise characteristics and other indicators. Welcome to inquire!

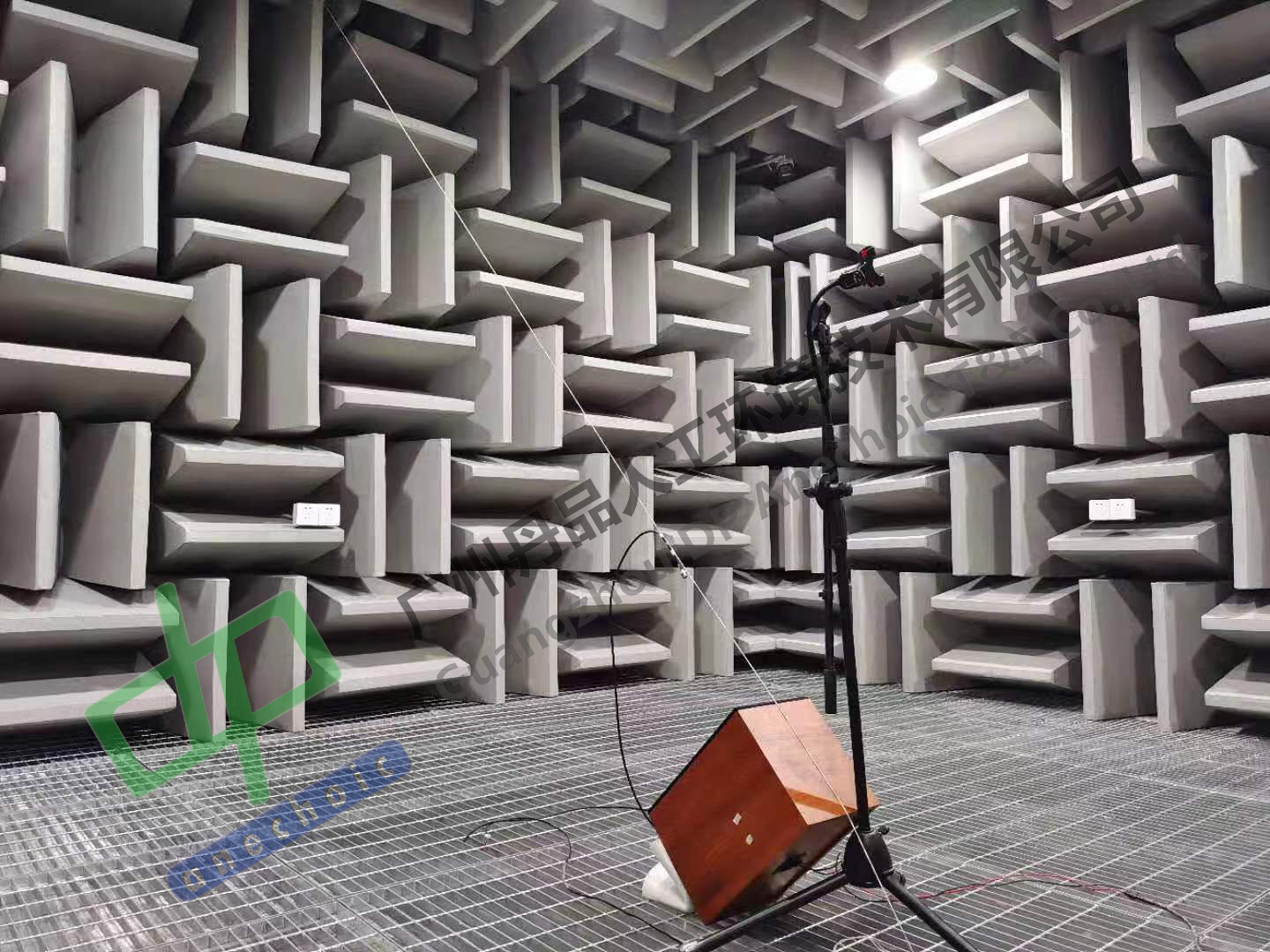

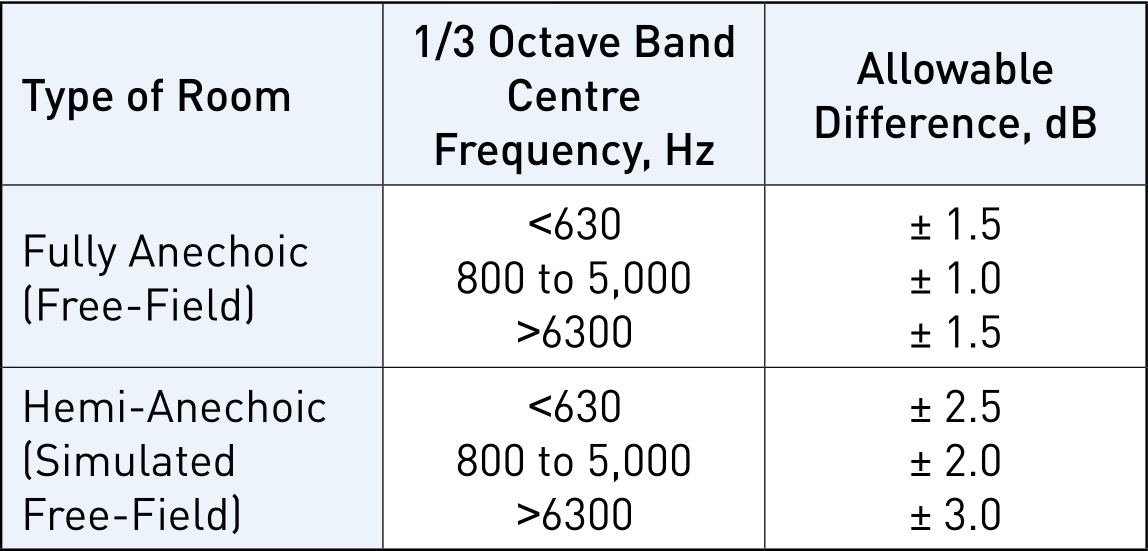

An anechoic chamber can be considered similar to a precision acoustical measurement instrument, providing a free-field environment without noise interference or sound reflection. In an ideal free-field environment, the inverse square law would function perfectly. This means that the sound level from a spherically radiating sound source decreases by 6dB for each doubling of distance from the source. For a free field to exist with perfect inverse square law characteristics, room boundaries must have a sound absorption coefficient of unity at all angles of incidence. In practice this is usually not quite perfect and deviations from the inverse square law are to be expected.Table 1 highlights the maximum allowable deviations

from the inverse square law as set out by ISO 3745 which states that “an anechoic room provides the preferred environment for measurements with the smallest uncertainty.”

Construction of Anechoic Rooms

For anechoic rooms to function well, a number of acoustic, mechanical, electrical and aerodynamic considerations apply. These will include some, or all, of the following:

• Anechoic treatment selection

• Cut-off frequency

• Internal acoustic ambient noise level

• Noise reduction

• Vibration isolation

• Silenced ventilation systems

• Acoustic doors – operation and sizing

• Interior floors – cables and / or gratings

• Lighting and electrical systems

• Overall structural design considerations

• RF shielding requirements

Noise & Vibration Isolation Characteristics

A well constructed room must provide good sound isolation against external noise so that resulting internal noise will not invalidate acoustic measurements. This may require the use of single or double-wall construction with appropriately designed vibration isolation to adequately reduce air – and / orstructure-borne noise transmission.For best results, anechoic facilities

should be individual structures,separate from any host building walls.

Anechoic Wedges

One practical well proven method to achieve a free-field is to shape sound absorbing material into wedge configurations for mounting on to the interior surfaces. The wedge shaped geometry ensures a gradual change in the acoustic impedance of the transmission media, ensuring that sound waves are absorbed by the material, rather than reflected at an interface.

The effectiveness of the absorption depends on the geometry and materials used. The lowest frequency at which the absorption is effective (cut-off frequency) is inversely proportional

to the depth of the wedge.DP’s own impedance tube is used for critical adjustment of wedge dimensions before finalising each design. Due to variations in material characteristics, statistical quality control measures are employed during wedge production to ensure specified acoustic performance.

Evaluation method of semi-anechoic chamber

In practical engineering, the free space of sound field is the key basis to identify the soundproof chamber. ISO 3745,. ANSI S12.55 and GB 6882 provide identification methods to identify the free space of semi-anechoic chamber.

In addition, the background noise is another important index of the semi-anechoic chamber. The measured background noise is the background noise of the instrument plus the background noise of the anechoic chamber.

II. Acoustic performance parameters of anechoic chamber

1. The size and main technical indicators of the anechoic chamber

anechoic chamber design standards ISO 3745,. ANSI S12.55 and GB 6882 ※

Cut-off frequency is 125Hz (it can be extended to 50Hz according to requirements) ※

Background noise is 16dB(A) (special design can reach 11dB(A). ※

External dimensions ※

Internal dimensions are designed according to requirements and standards. ※

Available space ※

2. Acoustic performance parameters

2.1 sound absorption performance

The wedge provided for installation meets the requirement that the sound absorption coefficient is 0.99 at the cut-off frequency (taking the wedge with the cut-off frequency of 125Hz as an example)

Frequency (Hz) sound absorption coefficient

125 0.99

250 0.99

500 0.99

1000 0.99

2000 0.99

4000 0.99

8000 0.99

2.2 noise elimination performance

anechoic chamber can provide an approximate semi-free field environment with a frequency range of 125Hz to 8000Hz, and its inverse square law performance deviation meets the requirements of the following international standards ISO 3745,. ANSI S12.55 and GB 6882:

The measurement requirement is to use a single frequency signal, which is selected at the center frequency of 1/3 octave.

2.3 Sound isolation performance

III. anechoic chamber assembly

3.1 Professional sound-absorbing wedge material (patent number: 200720155131.2)

Sampling super green sound-absorbing cotton, and curing the surface with glue. Dust-proof treatment technology is adopted between the glass and the veneer, which makes the wedge surface easy to clean and ensures long-term stable acoustic performance parameters.

3.2 wedge door (patent number: 200920279477.2)

The split door adopts metal perforated sound-absorbing split structure, which makes the split door and the internal split form a complete sound-absorbing surface. The split door adopts special hinge, which makes the opening and closing of the door easy and does not deform for a long time. When the split door is opened, it can be designed to be staggered with the split teeth of the inner wall, saving space.

3.3 Sound insulation door (patent number: 200920279477.2)

In the design of anechoic chamber (semi-anechoic chamber), the door is a very important factor. A good sound insulation door should have good sound insulation performance and optimal edge effect. 1.5mm thick cold-rolled steel plate, with molded sound-absorbing cotton inside, and imported hinge, the whole door will float when it is opened. When the door is closed, the high-density magnetic edge sealing strip is half-closed, ensuring that its acoustic treatment can match the acoustic treatment of other parts around it to eliminate the edge sound leakage as much as possible. The strength meets the operation requirements, and it will not be deformed after long-term use. At the same time, the outer surface is sprayed with plastic to make the color consistent with the wedge.